From Raw Steel to Reliable Fire & EMS Locker Systems

At GearGrid, every Fire & EMS Locker represents more than equipment storage—it’s the result of precision engineering, dedicated craftsmanship, and our unwavering pride in American manufacturing.

From the first delivery of raw steel coils to the final shipment of a completed unit, each stage of production is guided by one goal: to create durable, dependable solutions for the first responders who rely on them every day.

Precision & Care in Every Locker

Every weld, every finish, and every detail is handled with care, ensuring our lockers stand up to the toughest demands of the job. Because when firefighters and EMS crews trust us to protect their gear, we know we’re not just building lockers—we’re building confidence, safety, and long-lasting support for the people who serve their communities.

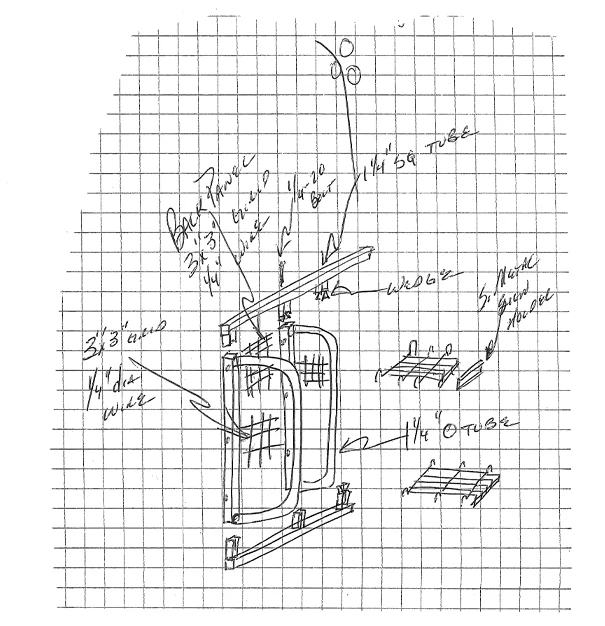

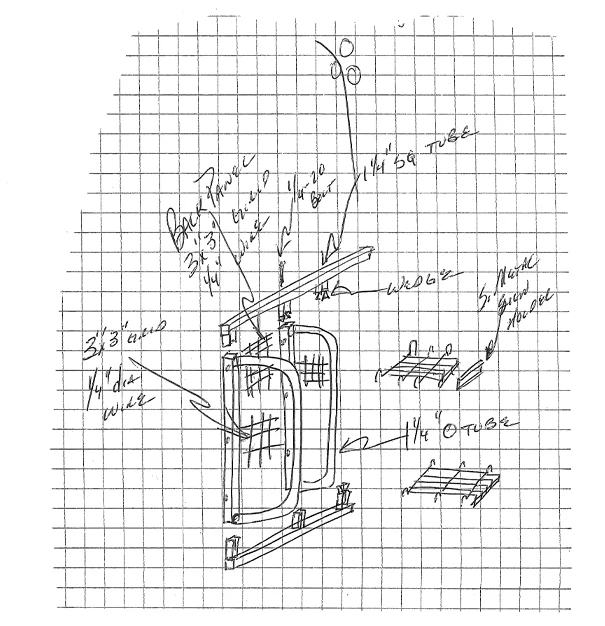

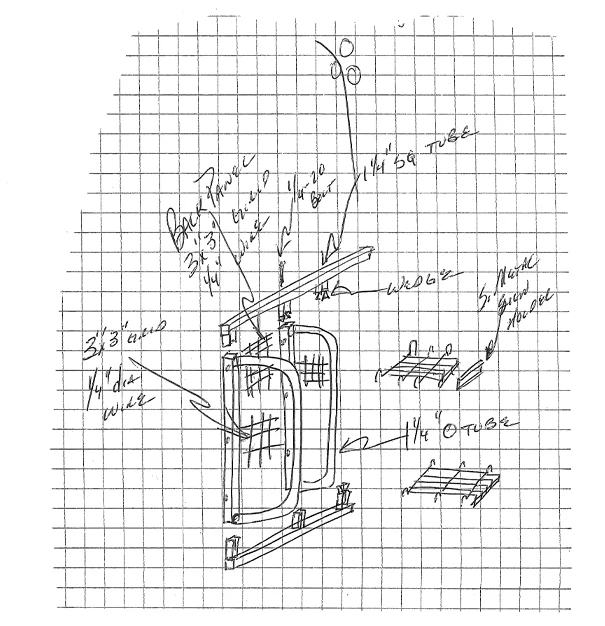

Phase One: From 1:1 Consultation to Custom Locker Design Planning

Every GearGrid product begins the same way—with a conversation. From the first phone call or email, you’ll connect with a dedicated GearGrid professional who’s here to guide you every step of the way. We take the time to understand your department’s unique needs, space, and goals so we can build a locker solution that truly fits your team.

Phase One: From 1:1 Consultation to Custom Locker Design Planning

From initial design discussions to final delivery, you’ll always have a real, trusted partner by your side. Someone who knows your order, answers your questions, and ensures every detail meets your expectations. That hands-on support continues throughout the entire process, right up until your lockers are installed and ready to serve your department.

Phase One: From 1:1 Consultation to Custom Locker Design Planning

Once your design is finalized, the real transformation begins in our 60,000 square foot Forest Lake, Minnesota facility—with raw steel, skilled hands, and the craftsmanship that defines every GearGrid locker.

Phase Two: Building the Foundation-Cutting, Bending & Welding

Every GearGrid locker begins its journey with high-quality steel coils of wire and bundles of tube, delivered and carefully organized at our facility. These raw materials form the foundation of every locker we create. By starting with premium steel, we ensure that strength and durability are built into every product from the very beginning.

Phase Two: Building the Foundation-Cutting, Bending & Welding

Once the steel materials arrive, they move through state-of-the-art machinery that straightens and cuts them into precise lengths, each piece measured to exact specifications. As these components take shape, the transformation from raw material to functional design begins.

Phase Two: Building the Foundation-Cutting, Bending & Welding

During the build, every locker goes through multiple stages of bending and welding, where the precision of automation meets the care of human craftsmanship. Our skilled fabrication team works alongside advanced equipment to ensure every joint, seam, and connection is perfectly aligned. It’s this balance of technology and human touch that creates GearGrid’s signature open-grid design—strong, consistent, and built to perform for years to come.

Phase Two: Building the Foundation-Cutting, Bending & Welding

No GearGrid locker is complete without the small plate welded onto the back panel that holds our logo—a subtle detail that reflects the care and intention behind each unit. It serves as a simple reminder of our commitment to building dependable storage solutions that support the firefighters and EMS crews who rely on them every day.

Phase Three: Finishing with Purpose-Washing, Powder Coating & Curing

Once each locker’s components are built, they’re carefully hung on our automated conveyer line—positioned so every part can move smoothly through the washing, powder coating, and curing stages. The process begins with a detailed wash that removes impurities, residue, and moisture, ensuring a clean, flawless surface for the finish that follows.

Phase Three: Finishing with Purpose-Washing, Powder Coating & Curing

After washing and drying, each part receives a hand-applied powder coat by our team. This careful application creates an even, durable finish that enhances both the look and long-term protection of every unit.

Phase Three: Finishing with Purpose-Washing, Powder Coating & Curing

Once coated, the parts move into an oven—typically between 350-400 degrees, where the powder bonds and cures to the steel. The components travel through the oven for approximately 25 minutes, allowing the finish to fully adhere and achieve its long-lasting durability. The result is a vibrant, high-quality coating that stands up to the toughest environments—and built to stay that way.

Phase Four: Trusted to Perform-Quality Tested, Packaged & Shipped with Care

Before a locker ever leaves our facility, it undergoes a rigorous final quality inspection. Every weld, every finish, and every detail is reviewed to ensure it meets GearGrid’s high standards for strength, durability, and appearance.

We know that first responders depend on our products daily, so nothing leaves our floor until it’s built to perform.

Phase Four: Trusted to Perform-Quality Tested, Packaged & Shipped with Care

Once approved, each locker is carefully packed by hand, with protective measures in place to help ensure it arrives in perfect condition. Whether the order is headed to a small-town fire station or a large metropolitan department, every shipment receives the same level of attention and respect.

Phase One: From 1:1 Consultation to Custom Locker Design Planning

Every GearGrid product begins the same way—with a conversation. From the first phone call or email, you’ll connect with a dedicated GearGrid professional who’s here to guide you every step of the way. We take the time to understand your department’s unique needs, space, and goals so we can build a locker solution that truly fits your team.

Phase One: From 1:1 Consultation to Custom Locker Design Planning

From initial design discussions to final delivery, you’ll always have a real, trusted partner by your side. Someone who knows your order, answers your questions, and ensures every detail meets your expectations. That hands-on support continues throughout the entire process, right up until your lockers are installed and ready to serve your department.

Phase One: From 1:1 Consultation to Custom Locker Design Planning

Once your design is finalized, the real transformation begins in our 60,000 square foot Forest Lake, Minnesota facility—with raw steel, skilled hands, and the craftsmanship that defines every GearGrid locker.

Phase Two: Building the Foundation-Cutting, Bending & Welding

Every GearGrid locker begins its journey with high-quality steel coils of wire and bundles of tube, delivered and carefully organized at our facility. These raw materials form the foundation of every locker we create. By starting with premium steel, we ensure that strength and durability are built into every product from the very beginning.

Phase Two: Building the Foundation-Cutting, Bending & Welding

Once the steel materials arrive, they move through state-of-the-art machinery that straightens and cuts them into precise lengths, each piece measured to exact specifications. As these components take shape, the transformation from raw material to functional design begins.

Phase Two: Building the Foundation-Cutting, Bending & Welding

During the build, every locker goes through multiple stages of bending and welding, where the precision of automation meets the care of human craftsmanship. Our skilled fabrication team works alongside advanced equipment to ensure every joint, seam, and connection is perfectly aligned. It’s this balance of technology and human touch that creates GearGrid’s signature open-grid design—strong, consistent, and built to perform for years to come.

Phase Two: Building the Foundation-Cutting, Bending & Welding

No GearGrid locker is complete without the small plate welded onto the back panel that holds our logo—a subtle detail that reflects the care and intention behind each unit. It serves as a simple reminder of our commitment to building dependable storage solutions that support the firefighters and EMS crews who rely on them every day.

Phase Three: Finishing with Purpose-Washing, Powder Coating & Curing

Once each locker’s components are built, they’re carefully hung on our automated conveyer line—positioned so every part can move smoothly through the washing, powder coating, and curing stages. The process begins with a detailed wash that removes impurities, residue, and moisture, ensuring a clean, flawless surface for the finish that follows.

Phase Three: Finishing with Purpose-Washing, Powder Coating & Curing

After washing and drying, each part receives a hand-applied powder coat by our team. This careful application creates an even, durable finish that enhances both the look and long-term protection of every unit.

Phase Three: Finishing with Purpose-Washing, Powder Coating & Curing

Once coated, the parts move into an oven—typically between 350-400 degrees, where the powder bonds and cures to the steel. The components travel through the oven for approximately 25 minutes, allowing the finish to fully adhere and achieve its long-lasting durability. The result is a vibrant, high-quality coating that stands up to the toughest environments—and built to stay that way.

Phase Four: Trusted to Perform-Quality Tested, Packaged & Shipped with Care

Before a locker ever leaves our facility, it undergoes a rigorous final quality inspection. Every weld, every finish, and every detail is reviewed to ensure it meets GearGrid’s high standards for strength, durability, and appearance.

We know that first responders depend on our products daily, so nothing leaves our floor until it’s built to perform.

Phase Four: Trusted to Perform-Quality Tested, Packaged & Shipped with Care

Once approved, each locker is carefully packed by hand, with protective measures in place to help ensure it arrives in perfect condition. Whether the order is headed to a small-town fire station or a large metropolitan department, every shipment receives the same level of attention and respect.

Phase Four: Trusted to Perform-Quality Tested, Packaged & Shipped with Care

From delivery to final assembly, our team remains committed to supporting customers every step of the way. As each locker leaves our facility, our commitment goes with it—ensuring your system has the reliability, care, and ongoing support it needs to serve your department well—day after day, year after year.

Phase One: From 1:1 Consultation to Custom Locker Design Planning

Every GearGrid product begins the same way—with a conversation. From the first phone call or email, you’ll connect with a dedicated GearGrid professional who’s here to guide you every step of the way. We take the time to understand your department’s unique needs, space, and goals so we can build a locker solution that truly fits your team.

Phase One: From 1:1 Consultation to Custom Locker Design Planning

From initial design discussions to final delivery, you’ll always have a real, trusted partner by your side. Someone who knows your order, answers your questions, and ensures every detail meets your expectations. That hands-on support continues throughout the entire process, right up until your lockers are installed and ready to serve your department.

Phase One: From 1:1 Consultation to Custom Locker Design Planning

Once your design is finalized, the real transformation begins in our 60,000 square foot Forest Lake, Minnesota facility—with raw steel, skilled hands, and the craftsmanship that defines every GearGrid locker.

Phase Two: Building the Foundation-Cutting, Bending & Welding

Every GearGrid locker begins its journey with high-quality steel coils of wire and bundles of tube, delivered and carefully organized at our facility. These raw materials form the foundation of every locker we create. By starting with premium steel, we ensure that strength and durability are built into every product from the very beginning.

Phase Two: Building the Foundation-Cutting, Bending & Welding

Once the steel materials arrive, they move through state-of-the-art machinery that straightens and cuts them into precise lengths, each piece measured to exact specifications. As these components take shape, the transformation from raw material to functional design begins.

Phase Two: Building the Foundation-Cutting, Bending & Welding

During the build, every locker goes through multiple stages of bending and welding, where the precision of automation meets the care of human craftsmanship. Our skilled fabrication team works alongside advanced equipment to ensure every joint, seam, and connection is perfectly aligned. It’s this balance of technology and human touch that creates GearGrid’s signature open-grid design—strong, consistent, and built to perform for years to come.

Phase Two: Building the Foundation-Cutting, Bending & Welding

No GearGrid locker is complete without the small plate welded onto the back panel that holds our logo—a subtle detail that reflects the care and intention behind each unit. It serves as a simple reminder of our commitment to building dependable storage solutions that support the firefighters and EMS crews who rely on them every day.

Phase Three: Finishing with Purpose-Washing, Powder Coating & Curing

Once each locker’s components are built, they’re carefully hung on our automated conveyer line—positioned so every part can move smoothly through the washing, powder coating, and curing stages. The process begins with a detailed wash that removes impurities, residue, and moisture, ensuring a clean, flawless surface for the finish that follows.

Phase Three: Finishing with Purpose-Washing, Powder Coating & Curing

After washing and drying, each part receives a hand-applied powder coat by our team. This careful application creates an even, durable finish that enhances both the look and long-term protection of every unit.

Phase Three: Finishing with Purpose-Washing, Powder Coating & Curing

Once coated, the parts move into an oven—typically between 350-400 degrees, where the powder bonds and cures to the steel. The components travel through the oven for approximately 25 minutes, allowing the finish to fully adhere and achieve its long-lasting durability. The result is a vibrant, high-quality coating that stands up to the toughest environments—and built to stay that way.

Phase Four: Trusted to Perform-Quality Tested, Packaged & Shipped with Care

Before a locker ever leaves our facility, it undergoes a rigorous final quality inspection. Every weld, every finish, and every detail is reviewed to ensure it meets GearGrid’s high standards for strength, durability, and appearance.

We know that first responders depend on our products daily, so nothing leaves our floor until it’s built to perform.

Phase Four: Trusted to Perform-Quality Tested, Packaged & Shipped with Care

Once approved, each locker is carefully packed by hand, with protective measures in place to help ensure it arrives in perfect condition. Whether the order is headed to a small-town fire station or a large metropolitan department, every shipment receives the same level of attention and respect.

Phase Four: Trusted to Perform-Quality Tested, Packaged & Shipped with Care

From delivery to final assembly, our team remains committed to supporting customers every step of the way. As each locker leaves our facility, our commitment goes with it—ensuring your system has the reliability, care, and ongoing support it needs to serve your department well—day after day, year after year.